Downstream Bioproduction

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation.

Downstream Bioprocessing

Intensify your downstream processes

Purification of biological materials, also known as downstream processing, is an essential step in the production of biopharmaceuticals. This includes several complicated processing steps, and downstream processing is alone responsible for about 80% of the entire production costs of biologics. Reducing time and costs for downstream processing is therefore essential for lowering total manufacturing costs and reduce time to market.

ArgusEye provides innovative sensor systems that can intensify downstream purification processes by enabling real-time, in-line detection of critical quality attributes and process parameters using integrated sensors. Available today is AugaOne™, a complementary add-on system for your existing chromatography units that shortens the development time and increases productivity by providing specific in-line real-time data from day one.

Case Study

In-line detection of mAb breakthrough during Protein A chromatography

Product breakthrough is an important parameter to determine during process development for optimization of the capture chromatography step. Selecting the most efficient column resin for efficient purification with scale-up capabilities is a time-consuming and costly operation that requires several purification cycles including a substantial amount of off-line analytics.

By adding a sensor from ArgusEye to your chromatography system, its possible to measure product breakthrough directly during purification, saving previous time during process development.

- Highly sensitive detection of product breakthrough

- No sample pre-treatment needed

- Replace time-consuming off-line analysis

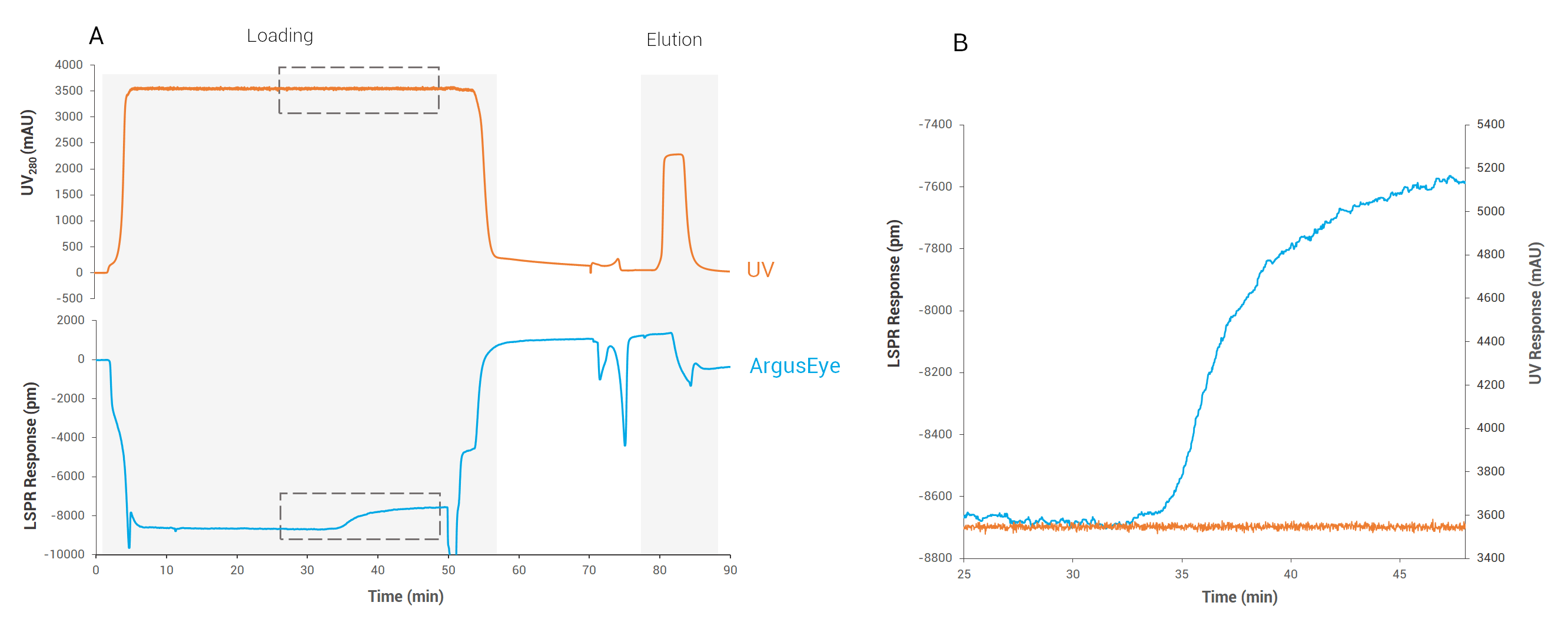

Below is an example showing detection of mAb breakthrough during Protein A chromatography (A) using our system AugaOne™. No breakthrough can be seen from the UV-signal due to saturation of the signal, but with AugaOne™ the mAb breakthrough can clearly be seen after about 35 minutes (B).

Case Study

Detection and quantification of IgG aggregates

Formation of aggregates during production of IgG is a constantly recurring problem which requires additional purification steps and off-line analysis. However, it is very important to remove these from the end-product since aggregates can induce a different therapeutic response compared to monomeric IgGs.

ArgusEye are developing an in-line sensor that can detect and quantify the amount of aggregates present in the sample directly during the purification procedure. Real-time quantification of aggregates can significantly reduce time needed for off-line analysis and provide direct information about the need for further processing steps.

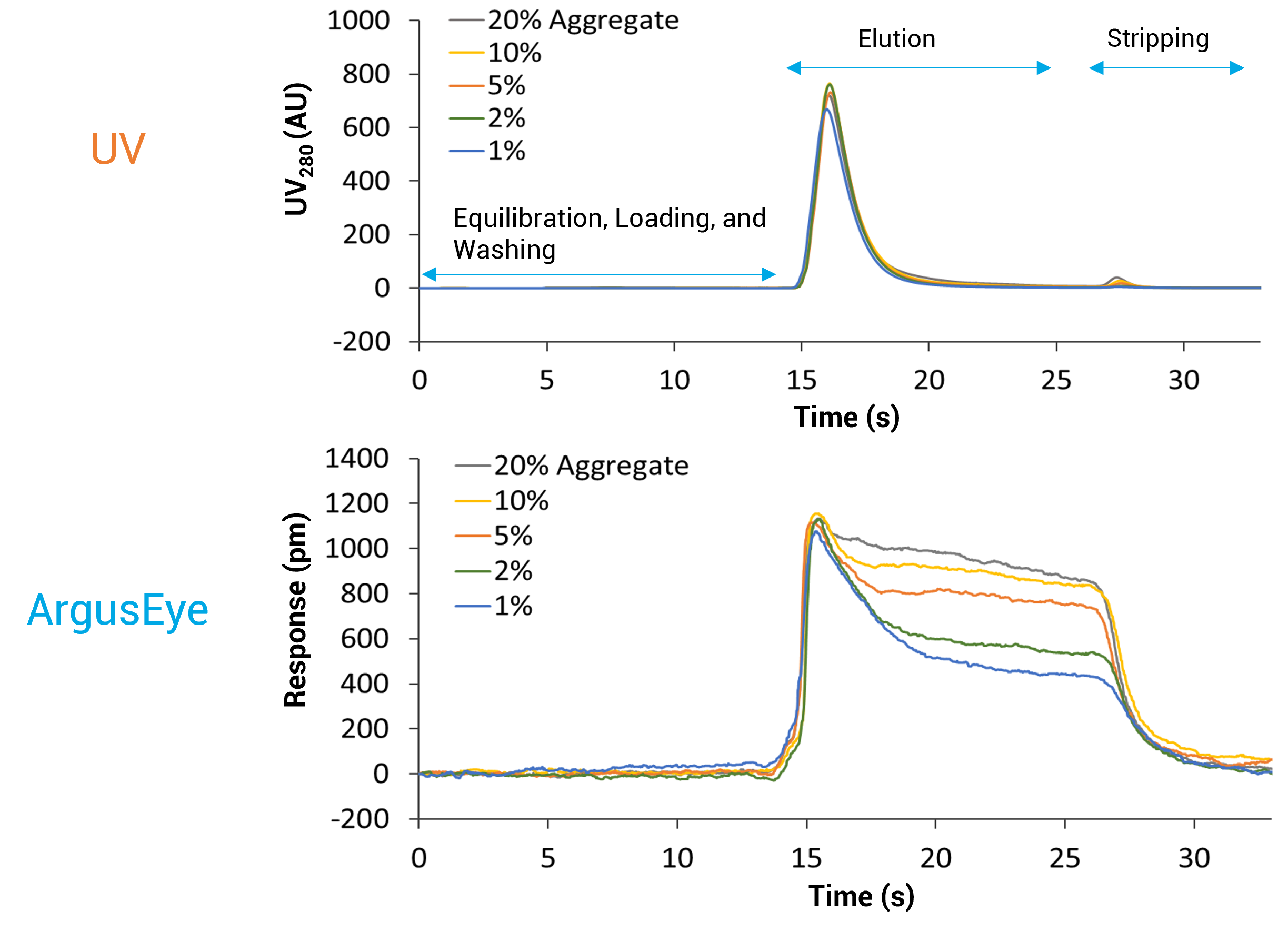

In the experiment below, we compared five different IgG samples with aggregates ranging from 1 to 20%. In the UV-signal, no difference can be seen for the different samples but with a sensor from ArgusEye it is possible to detect and differentiate samples with different aggregate levels.

- Aggregate levels in the elution pool can be measured in real-time

- Lower aggregate levels (<1%) can be determined if higher load is used