Upstream Bioprocessing

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Upstream Bioprocessing

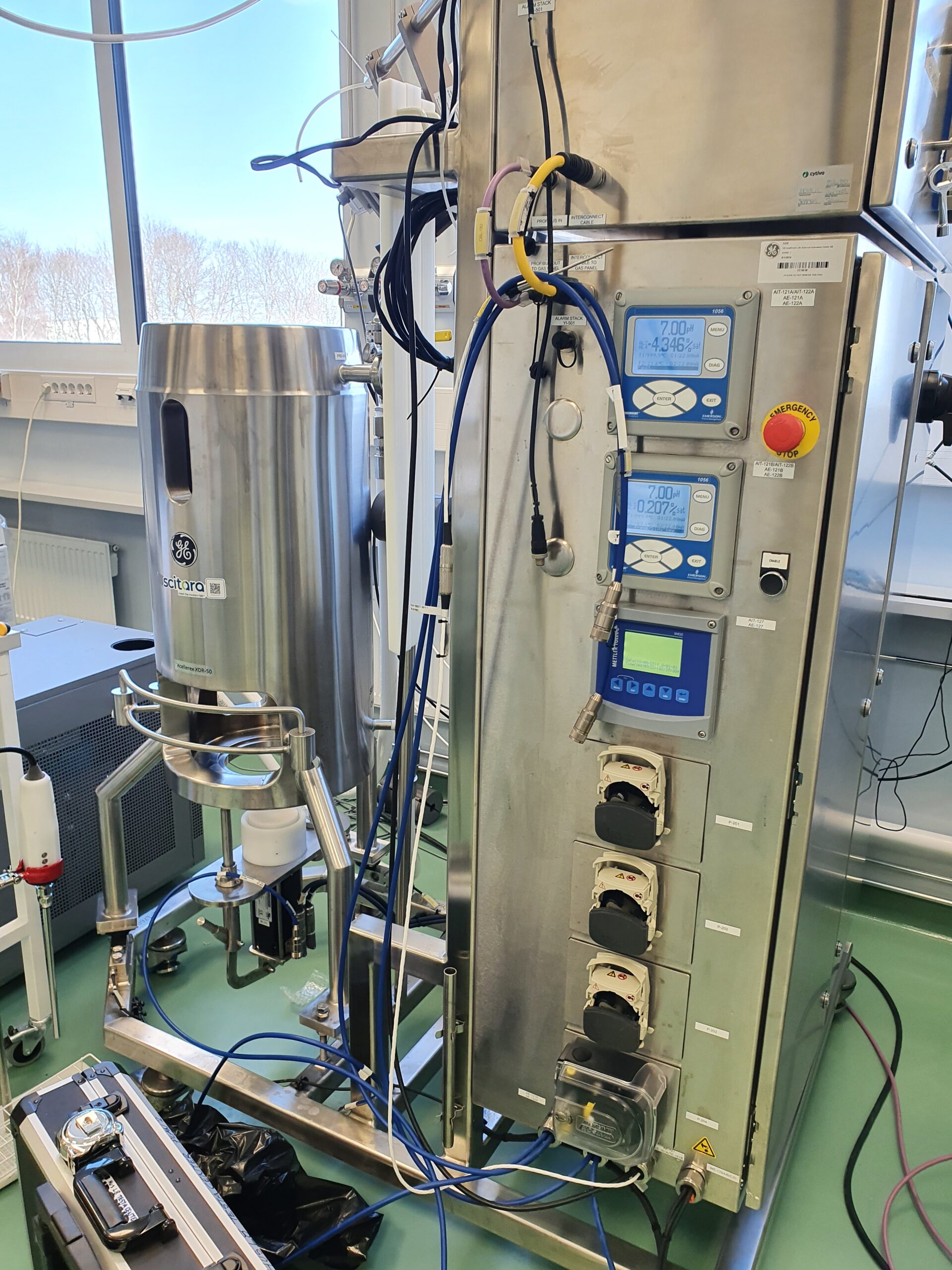

Sensor systems for monitoring upstream processes – coming soon

Accelerate upstream development with faster analytics

Development, optimization, and up-scaling of cell culture processes are critical steps in the process of developing new biological drugs. Integrated sensors that measure important process parameters and critical quality attributes in real-time can significantly speed up process development with increased efficiency and productivity compared to off-line testing.

Nanoplasmonic sensing has great potential for in-line/on-line monitoring of upstream processes since its possible to create flexible sensor configurations that can be integrated into various processing steps and measure critical process parameters such as product titer, product variants, or process contaminates in complex sample matrixes.

Case Study

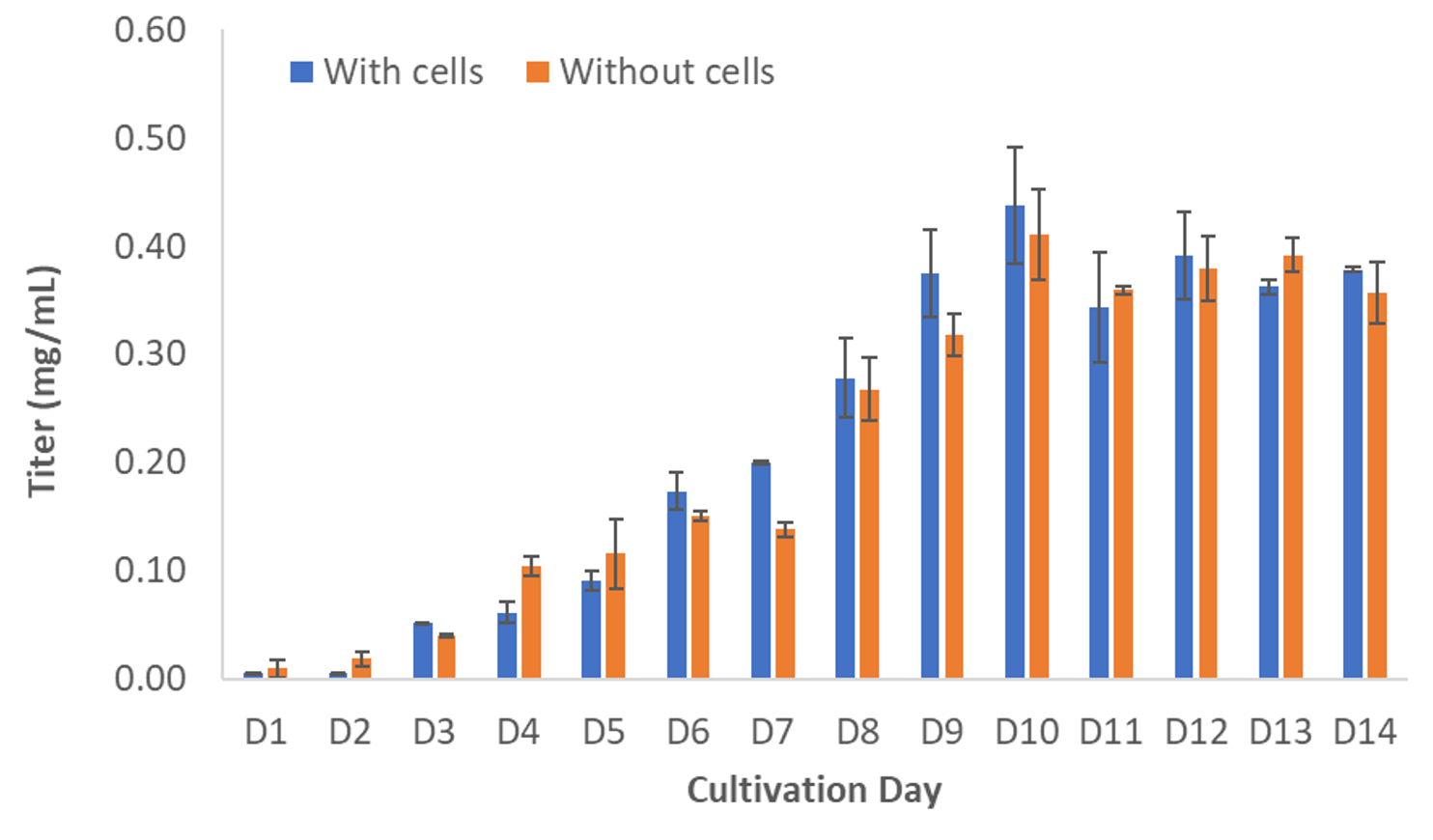

IgG titer quantification in samples with cells

The ArgusOne system was used for rapid at-line quantification of IgG in samples extracted directly from a cell culture. The IgG titer was determined in samples with and without removal of the cells.

- No sample treatment needed

- Quick ~2 minutes

- Low sample volume (100 µL)